Steel vs metal: what’s the difference?

Often similar in look and feel, it’s no wonder the terms ‘steel’ and ‘metal’ are commonly, yet mistakenly, interchanged.

Here, we investigate the differences between these common materials and showcase Edcon Steel’s range of products that suit just about any application.

A brief history of iron

In order to understand the difference between steel and metal, we first need to understand iron.

Iron is a naturally occurring element, (like other metals such as zinc and copper), and our ancestors originally extracted it from a handful of meteorites that had crashed into the earth.

It was thousands of years before our ancestors discovered a stockpile of ore (iron mixed with stones and other metals) hiding beneath the earth’s surface – and yet another 700 years before they discovered the magic process of extracting iron from the ore.

It was this ‘smelting’ process that would change the course of history.

The ‘magic’ process

In the iron smelting process, where iron ore is heated beyond its melting point in special conditions, a chemical reaction takes place where the iron absorbs carbon (in a process called ‘alloying’).

When the iron absorbs too little carbon (usually less than 0.08%), the result is a soft, ductile and fibrous material – wrought iron.

But when we add too much carbon to the iron (from 2-4%), it becomes hard and brittle – what’s known as cast iron.

The magic of steel is in a subtle change to this alloying process – a very specific carbon content and a unique way of alloying.

The first magic happened in India, around 400BC when people added the perfect amount of carbon to iron (between 0.5% and 1.5%).

This minute change was so small, but it changed everything – steel was born. This ‘magic’ process and its wondrous by-product quickly spread throughout the world, undergoing many tweaks and adjustments to the production process over thousands of years to what we know today – one of the most common man-made materials in the world, with more than 1.6 billion tonnes produced annually.

And while metals are the building blocks of steel, they are also used independently, for their own applications that require their unique properties.

Steel applications

Stronger, tougher and more versatile than most metals – and in abundant supply – steel has transformed the world.

The creation of structures like skyscrapers, trucks, cars, as well as furniture and many household products would not be possible without steel.

The alloying process is what makes steel so unique. Small changes to alloying mixes, especially the carbon content, can affect micro-structures and, therefore, mechanical properties.

This changes the characteristics of the steel and its suitability for different applications.

For example, if you require very strong steel that is weldable, then low carbon steel, alloyed with manganese or nickel will be the best option, as it has high strength and good weldability. High carbon steel, however, is too brittle for welding.

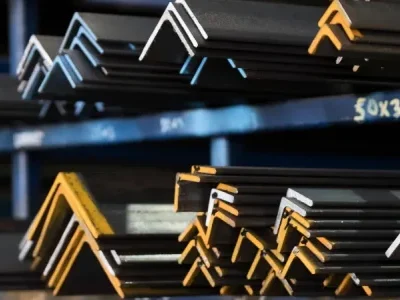

There are thousands of types of steel, each manufactured to suit many types of applications, but these generally fall into four broad categories: mild steel, stainless steel, tool steel and carbon steel. View Edcon’s range of steel products below.

Mild Steel

| Carbon Content | Product | Description |

| Low | 300 Plus | Generally hot rolled mill finish, this is a relatively low tolerance coarse finish bar with mill scale. Buy online. |

| Low | C250LO | Known as pipe, schedule pipe or line pipe, steel hollow sections are available in a wide variety of types and sizes to suit all manner of applications. Based on ASTM sizes, we stock mild steel pipes to Australian Standards. Buy online. |

| Low | C350LO | Rectangular Box Sections or RHS tubes are available in dual grade or 350 grade mild steel. Buy online. |

| Low | 1214 | A free-machining, low-tensile carbon steel typically supplied in cold drawn or turned and polished condition. Excellent machinability, moderate weldability and reasonable strength and ductility. With very low hardenability, it is frequently used across industry sectors for parts and components requiring extensive machining. Buy online. |

| Low | 1020 | Bright Mild Steels (BMS), used extensively in the engineering and construction industries, can be substituted for hot-rolled or forged steel (black steel). Characteristics include improved surface finish, enhanced mechanical properties and better machinability arising from cold drawing or cold rolling. Buy online. |

| Low | 1030 | While Edcon Steel normally stocks 1020 grade, 1030 and 1040 may be available, subject to enquiry. Enquire now. |

| Low | 4140 | A general-purpose steel bar or steel plate with extreme versatility. Low alloy, containing molybdenum, manganese and chromium. With increased carbon content, it is characterised by high fatigue strength, abrasion and impact resistance, plus heat treatment capabilities. Buy online. |

| Low | 4340 | 1% chromium-molybdenum (chrome-moly) high-tensile, steel alloy bar. Available in round bars. Enquire now. |

| Low | EN26 | 2.5% nickel-chromium-molybdenum alloy steel with a higher carbon content. Supplied in hardened and tempered condition. Enquire now. |

| Low | 750HB | 20MnV6 is a carbon-manganese steel micro alloyed with vanadium, generally supplied in the black hot rolled condition. Buy online. |

| Low | EN36A | A nickel-chrome, case-hardening steel with high hardenability and core strength. Typical applications include highly stressed gears and heavily loaded shafts. Buy online. |

Stainless Steel

| Carbon Content | Product | Description |

| Low | 304 Stainless Steel | 304 grade stainless steel is an entry level austenitic stainless steel with superior corrosion protection than uncoated mild steel. Buy online. |

| Low | 316 Stainless Steel | 316 grade stainless steel (marine grade) has a greater level of corrosion resistance than 304 grade stainless steel (furniture grade). Buy online. |

| Low | 431 Stainless Steel | 431 is a martensitic, nickel-bearing grade which has good corrosion resistance, excellent tensile and torque strength and good toughness. Enquire now. |

| Low | 2205 Duplex | 2205 is a duplex stainless steel with high general, localised and stress corrosion resistance properties in addition to high strength and excellent impact toughness. Enquire now. |

Medium Carbon Steel

| Carbon Content | Product | Description |

| Medium | 1045 | Fully killed (deoxidised) medium carbon steel. Buy online. |

| Medium | 1045 Chrome Bar | Used in standard cylinders, dump trucks, fork lifts, presses, gates and automotive doors, steering-gear systems, lifts, hydraulic platforms, cranes, drilling equipment and garbage compactors. Buy online. |

| Medium | 01 | A general purpose tool steel suitable for a wide variety of cold work applications. Characteristics include good machinability and a good combination of high surface hardness and toughness after hardening and tempering. Buy online. |

High Carbon Steel

| Carbon Content | Product | Description |

| High | 2P Cast Iron | Known for its exceptionally good wearing qualities and superior mechanical and physical properties to those of a soft, (essentially ferritic) cast iron that was centrifugally cast. Enquire now. |

| High | 3D Cast Iron | Also known as BU DUCTILE CI, a spheroidal graphite (nodular) ductile iron, this is an essentially ferritic grade cast iron, having high elasticity and resistance to impact. It can be welded but cannot be readily flame or induction hardened. Enquire now. |

Metal applications

While steel may be the superior choice of material for many applications, metals – like copper, bronze, brass and aluminium – are ductile and malleable, making them a great material of choice for a wide range of applications.

Used from jewellery making through to engineering, electrical and construction, metals have high lustre and conductivity.

And while they are generally more expensive than steel, they can be far easier to work with for many applications.

View Edcon’s range of metal products below.

Metals

| Carbon Content | Product | Description |

| Nil | LG2 Bronze | Continuous cast bronze bar, also available in hollow bars, has greatly improved physical properties compared to normal sand cast material due to the elimination of inclusions. Buy online. |

| Nil | PB1 Bronze | Bronze grade with good machining properties and high strength. Enquire now. |

| Nil | 954 Aluminium Bronze | Very hard and abrasive resistant, it has excellent strength and wear resistance with reasonable machining properties. Physical properties remain stable at elevated temperatures. Enquire now. |

| Nil | Brass | Good corrosion resistance to fresh water. Should not come into contact with ammonia compounds or be immersed in salt water. Will weather to a warm bronze colour. Buy online. |

| Nil | Copper | Excellent corrosion resistance and can be used in underground applications, as it resists soil corrosion. Generally resists mineral, fatty and organic acids, depending on concentration and specific conditions. Buy online. |

| Nil | 2011 Aluminium | High mechanical strength alloy that machines exceptionally well. Allows production of detailed parts. Buy online. |

| Nil | 3003 Aluminium | Medium strength, good weldability and good corrosion resistance in marine and seawater applications. Commonly used as sheet and plate forms. Buy online. |

| Nil | 5005 Aluminium | Medium strength, good weldability and good corrosion resistance in marine applications. Commonly used as sheet and plate forms. Buy online. |

| Nil | 5052 Aluminium | Medium strength, good weldability and good corrosion resistance in marine applications. Commonly used as sheet and plate forms. Buy online. |

| Nil | 6060 Aluminium | Medium strength heat treatable alloy with good corrosion resistance and very good weldability. Buy online. |

| Nil | 6061 Aluminium | Heat treatable alloy of medium strength. Enquire now. |

Edcon’s steel and metal products

Edcon Steel offers our customers complete steel and metal solutions – online and in-store (subject to COVID-19 restrictions).