News and Articles

Steel and Metal Articles

Categories

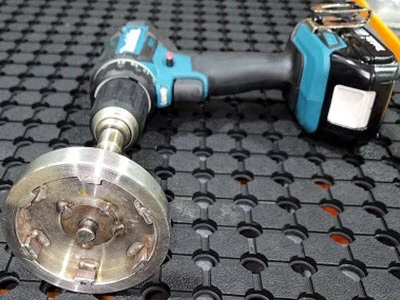

Custom drill bit: a genius hack for an ongoing problem

Read more

Making waves: constructing a wave energy converter with Edcon’s stainless steel

Read more

The Pinkies win big at the Australian SLS Championships

Read more

An incredible motorised servery window wins our stainless steel project competition

Read more

Your industrial products supplier

Read more

Steel price respite

Read more

Edcon sponsorships: supporting our community

Read more

Indoor vertical farm

Read more

Incredible handmade armour

Read more