Beginners Guide to Steel: Stainless steel tube

Stainless steel tube is a versatile and durable material widely used across various industries. Known for its corrosion resistance, strength, and aesthetic appeal, stainless steel tube is a preferred choice for numerous applications. This article explores the key uses and benefits of stainless steel tubing in different sectors.

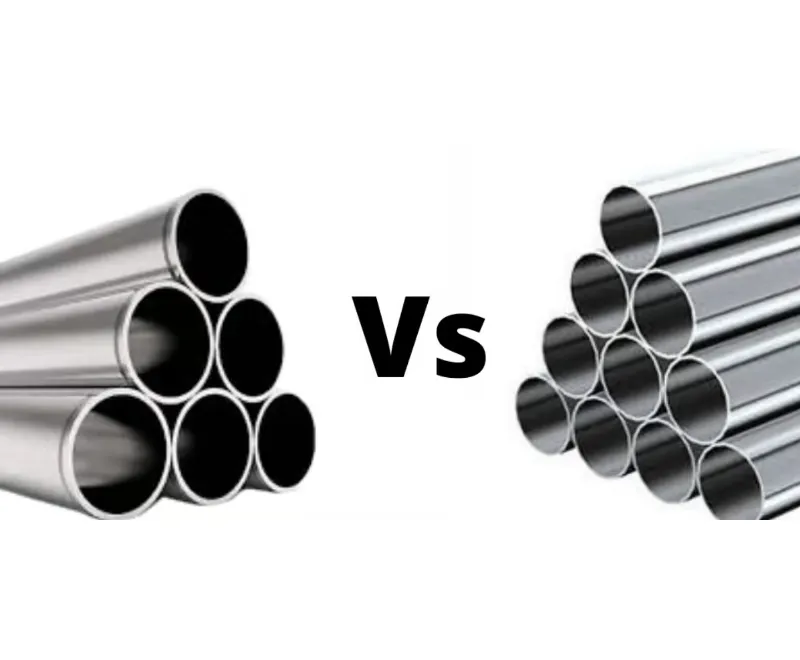

Stainless steel tube vs pipe

Stainless steel tubes are hollow, cylindrical structures used both as components in machinery and as conduits for fluid transport.

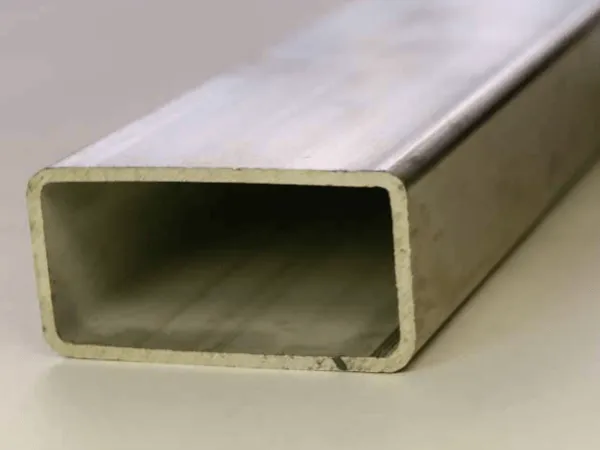

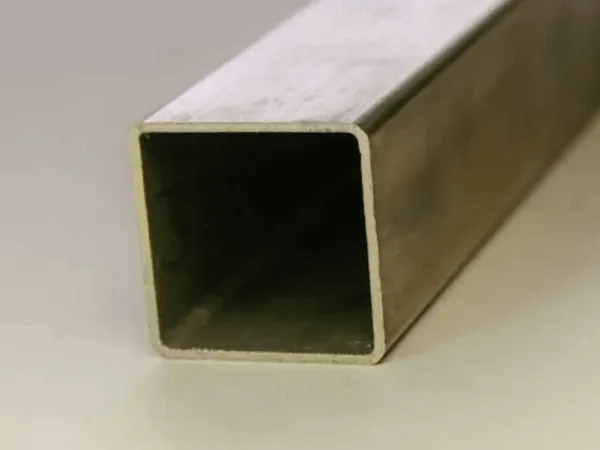

Many people confuse piping and tubing, as both have a circular cross-section and are often thought to serve similar purposes. However, unlike pipes, which are typically round, tubes can also come in shapes like square and rectangular.

A key distinction between pipes and tubes lies in their applications. Piping is primarily used for transporting gases and liquids and is measured by its internal diameter (NB – Nominal Bore which is a nominal size based on the OD less the thickness twice). In contrast, tubing predominantly serves architectural roles and is measured by its external diameter and wall thickness.

Stainless steel tube incorporates a comprehensive range of stainless steel fittings, including elbows, tees, reducers, and flanges, in various sizes, wall thicknesses, grades, and finishes to suit tube dimensions and tolerances.

Understanding stainless steel grades

To understand the various applications of stainless steel tubing, we must first delve into the various grades.

While stainless steel is the general term for a group of corrosion-resistant alloy steels, multiple grades of stainless steel exist. Each grade has a slightly different alloy composition and, therefore, slightly different physical characteristics, which are important for selecting the correct properties for your application.

Two of the most common stainless steel grades are 304 and 316. Each grade contains specific alloying ingredients that make it suitable for different applications. Understanding the differences between 304 and 316 stainless steel is important when choosing the right steel for your project.

316-grade stainless Steel, commonly referred to as “marine grade,” is extensively used in marine, food, and chemical processing equipment. It is used when better corrosion resistance is required than chromium-nickel (304-grade) stainless steel.

Browse Edcon’s range of stainless steel

Applications of stainless steel tube

Stainless steel tubing is famous for its strength, resistance to corrosion, and minimal maintenance requirements, which make it a favoured material across industries. The choice of tubing type depends on the specific application and can include fractional, hypodermic, square, or metric tubing.

1. Construction and Architecture

In the construction industry, stainless steel tubes are valued for their durability and structural integrity. Once installed, stainless steel requires minimal maintenance. Its resistance to staining and corrosion means it doesn’t need regular coatings or treatments. Stainless steel tubing has numerous applications in construction and architecture, including:

- Structural Framework: Stainless steel tube provides strong support in buildings and bridges, ensuring longevity and resistance to environmental factors.

- Handrails and Balustrades: Their sleek finish and resistance to rust make them ideal for railings in both commercial and residential properties.

- Facades: Stainless steel tube features heavily in modern architectural designs, offering both aesthetic appeal and functionality.

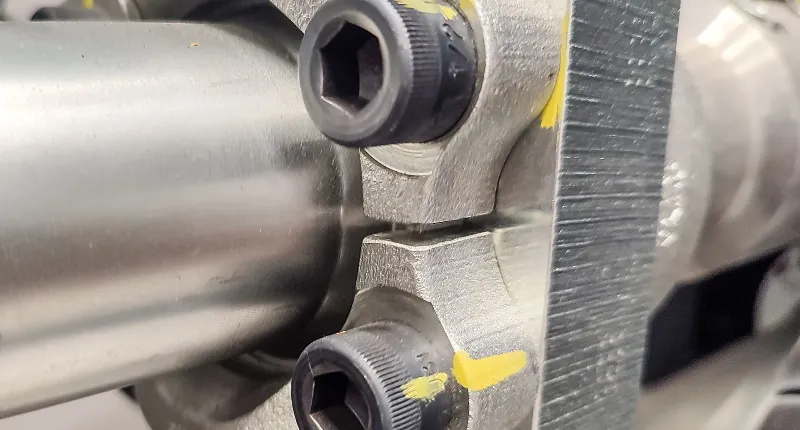

This motorised server window, completed by Edcon Steel customer Martin Roberts, is a perfect example of the application of stainless steel tube.

2. Automotive Industry

The automotive sector has increasingly adopted stainless steel tubes for various applications, including:

- Exhaust Systems: The heat and corrosion resistance of stainless steel tubing make it perfect for exhaust pipes, enhancing vehicle durability.

- Fuel Lines: Stainless steel tubing is used in fuel delivery systems, providing a reliable and leak-proof solution.

- Chassis Components: The lightweight yet strong nature of stainless steel tubing contributes to overall vehicle performance and safety.

3. Food and Beverage Industry

In the food and beverage sector, hygiene and corrosion resistance are paramount. The non-porous surface of stainless steel does not

harbour bacteria, mould, or other contaminants, which is crucial in maintaining hygiene standards. It can be easily cleaned and sanitised, reducing the risk of foodborne illnesses. Stainless steel tubing is widely used in:

Piping Systems: Used to transport liquids, including water and various beverages, while ensuring that the contents remain uncontaminated.

Processing Equipment: Stainless steel tubing is often used in equipment that processes food and drinks, from brewing tanks to dairy processing.

4. Chemical Processing

The chemical industry utilises stainless steel tubing due to its resistance to corrosive substances and ability to withstand high temperatures without warping or degrading. Key applications include:

- Piping Systems: For transporting chemicals safely and efficiently, stainless steel tubes provide the necessary durability.

- Heat Exchangers: Their thermal conductivity and resistance to chemical reactions make them ideal for heat exchange applications.

5. Energy Sector

Stainless steel tubing is essential in the energy sector due to its strength and resistance to extreme environments. They are used in:

Pipeline Construction: Stainless steel tubes provide reliable solutions for transporting oil and gas, minimising the risk of leaks.

Pressure Vessels: Their ability to withstand high pressure makes them suitable for various pressure vessel applications.

A wonderful example of a stainless steel tube being applied to the energy sector is Edcon Steel customer Callum Mainstone’s project. Callum used a variety of 316 stainless steel to construct a modular wave energy converter for his clean energy start-up business, Plithos Renewables.

Buy steel online from Edcon Steel

At Edcon Steel, we pride ourselves on the expertise of our staff, our level of customer service and the depth of our local market knowledge.

You can visit our stores to browse the range or pick up an online order. Our staff are on hand to answer any questions you have about our full range of products and services, so feel free to contact us for your steel or metal solution today.