Stainless steel pipe, tube and hollow bar

The latest edition of our beginner’s guide to steel is all about stainless steel pipe, tube and hollow bar. While each of these products are stainless steel bars with hollow centres, there are key differences in characteristics and applications.

Here, we delve into the differences between these popular items so you choose the right material for your next project.

Key differences in characteristics

Stainless steel pipes, tubes, and hollow bars have key differences in characteristics.

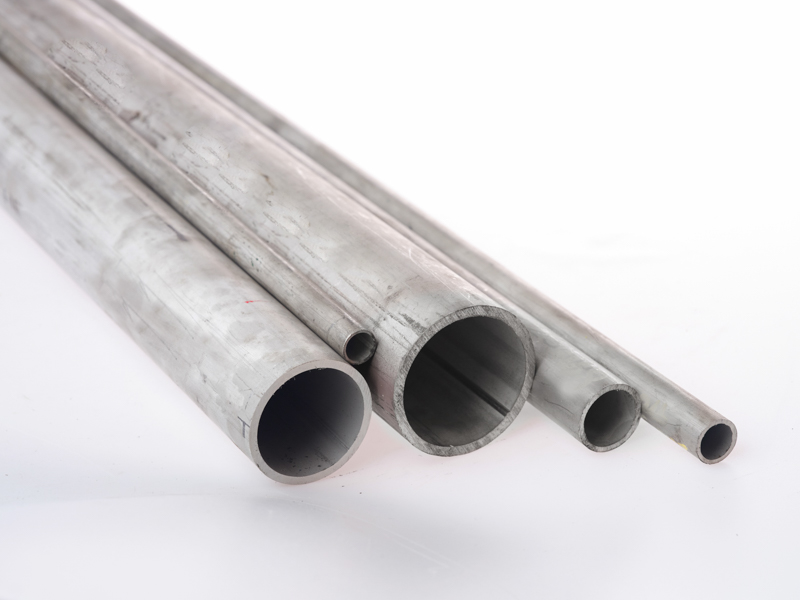

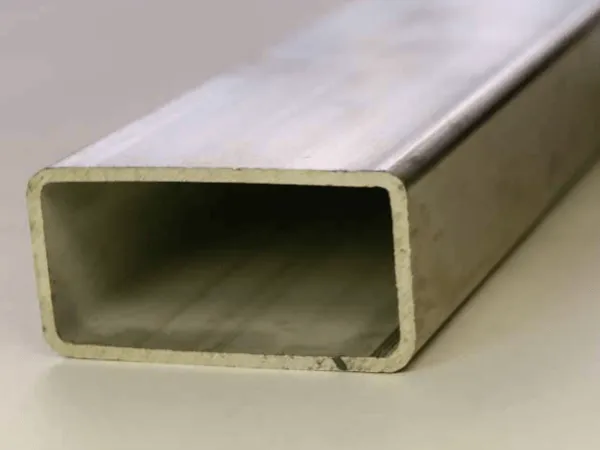

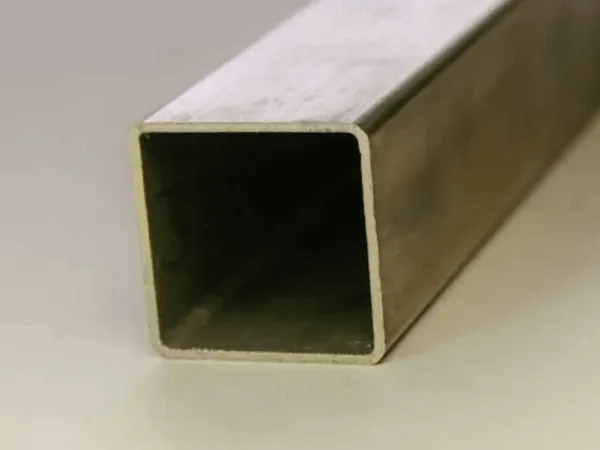

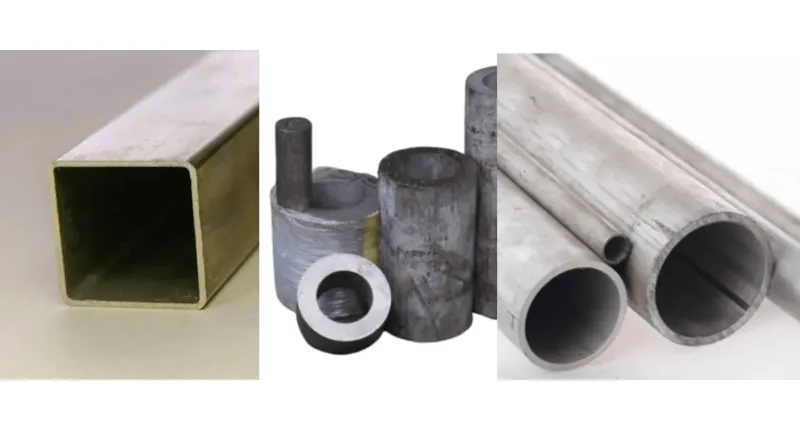

Firstly, there are notable differences in shape and structure. Stainless steel pipes are always round, whereas stainless steel tubes can be round (CHS), square (SHS), or rectangular (RHS). A stainless steel hollow bar is always round, but the walls are typically much thicker than either pipe or CHS.

There are also differences in dimensions and standards. While a stainless steel pipe is measured by its nominal (or inner) diameter and its wall thickness, a stainless steel tube is measured by its outside dimension. Hollow bars are measured similarly to tubes but focus on dimensions suitable for machining, with thicker walls for strength.

Browse Edcon’s range of engineering steel

Key differences in applications

Stainless Steel Pipes:

Stainless steel pipes are primarily designed for the transportation of fluids and gases and are used heavily in the oil, gas, food, beverage and water industries. Their standardised dimensions and wall thicknesses are well-suited for fluid dynamics, making them ideal for plumbing, chemical processing, and energy applications. Their strength and corrosion resistance make them ideal for both onshore and offshore applications.

Stainless steel tubes:

Versatile in design and use, stainless steel tubes cater to both structural and aesthetic applications and are common in automotive, medical, and architectural fields. Manufactured to tight tolerances, stainless steel tubes are ideal for applications that require precise specifications. Stainless steel tubes are used in automotive applications for exhaust systems, fuel lines, and structural components, where strength and resistance to high temperatures are critical. Tubes are popular in furniture design and architectural applications due to their aesthetic appeal, corrosion resistance and structural strength. They are often used in handrails, frames, and decorative elements.

Stainless Steel Hollow Bars:

Stainless steel hollow bars typically have thicker walls than pipes and tubes, providing sufficient material for machining (typically on a lathe) into various components. Often used in hydraulic applications, stainless steel hollow bars are utilised to create cylinders and flange components that can withstand high pressures and harsh conditions. These bars are also employed in applications where strength and durability are paramount, such as in heavy machinery and equipment.

It is important to note that the stated sizes of hollow bars are nominal sizes. They are typically machined to a size, and the dimensions shown are the final dimensions achieved after machining. They would usually be between 2-3 mm larger on the outside and 2-3 mm smaller on the inside. This will vary according to the manufacturer and even the batch.

Buy steel online from Edcon Steel

At Edcon Steel, we pride ourselves on the expertise of our staff, our level of customer service and the depth of our local market knowledge.

You can visit our stores to browse the range or pick up an online order. Our staff are on hand to answer any questions you have about our full range of products and services, so feel free to contact us for your steel or metal solution today.