How to maintain stainless steel

Known for looking clean and polished, stainless steel is a favourite for interior, exterior and industrial steel applications.

But while stainless steel is extremely durable and looks fantastic, without regular maintenance and the right types of cleaning, it can start looking a little worse for wear and eventually become permanently damaged.

Here, we talk you through how to correctly maintain stainless steel.

Why does stainless steel stain?

Many customers become frustrated when brown stains or rust appear on their ‘stainless’ steel, and rightly so.

So, let’s break down what stainless steel is and why it can stain.

While all steels have the same foundational iron and carbon composition, stainless steel is the general term for a group of corrosion-resistant alloy steels that contain ≥ 10.5% chromium. Chromium is the alloying element that allows stainless steel to withstand prolonged atmospheric exposure and use before showing signs of wear or corrosion.

While both carbon steel and stainless steel contain iron – which oxidises when exposed to the environment – the added chromium in stainless steel makes it more corrosion-resistant than other types of steel.

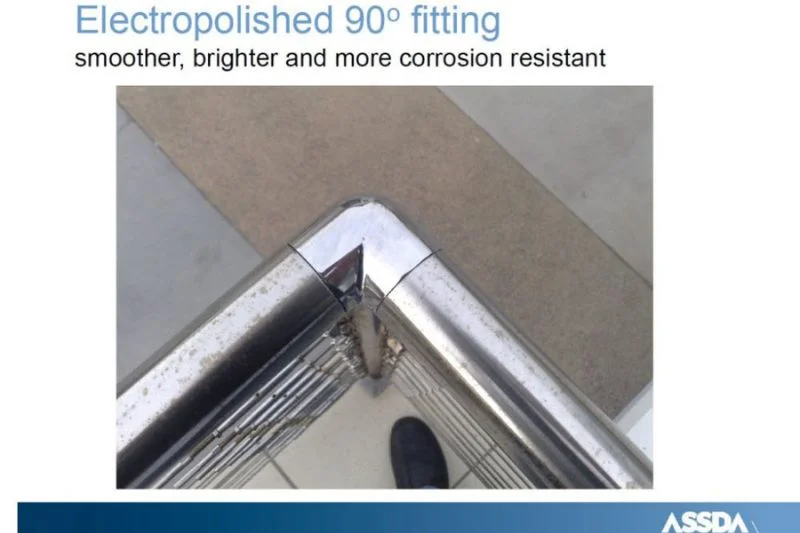

So, without a lengthy chemistry lesson, those tea-coloured stains are due to the finish (surface roughness) and cleanliness of your stainless steel.

As a rule, the smoother the finish on your stainless steel, the less likely there will be small craters and crevices for contaminants to react (i.e. rust) to your stainless steel.

Choosing the right grade of stainless steel

Choosing the right grade of stainless steel is a vital first step, as the selection must have adequate corrosion resistance for the application’s environment.

While there are more than 60 grades of stainless steel, all are divided into five main types, typically based on their nickel content. Each group has different characteristics, and there are several grades within each group.

For the purposes of this article, we will cover the most popular type, austenitic stainless steel. If you would like to learn more about stainless steel, we answer six common questions here.

Austenitic stainless steel

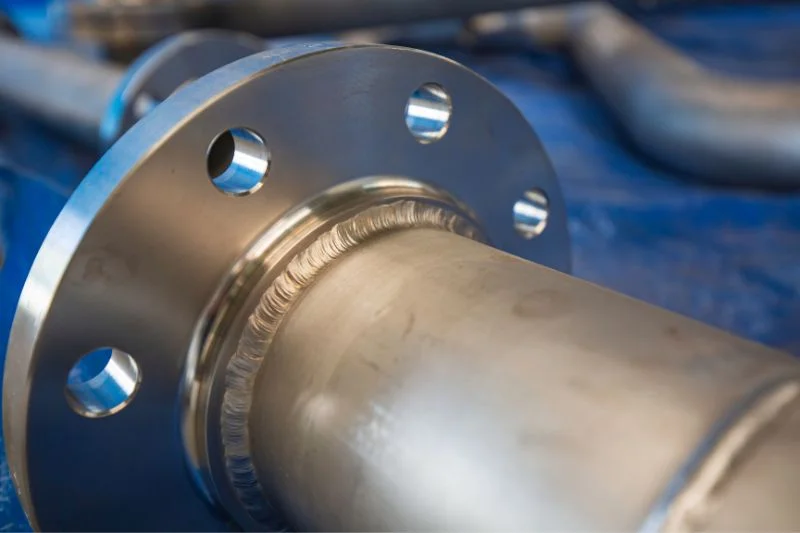

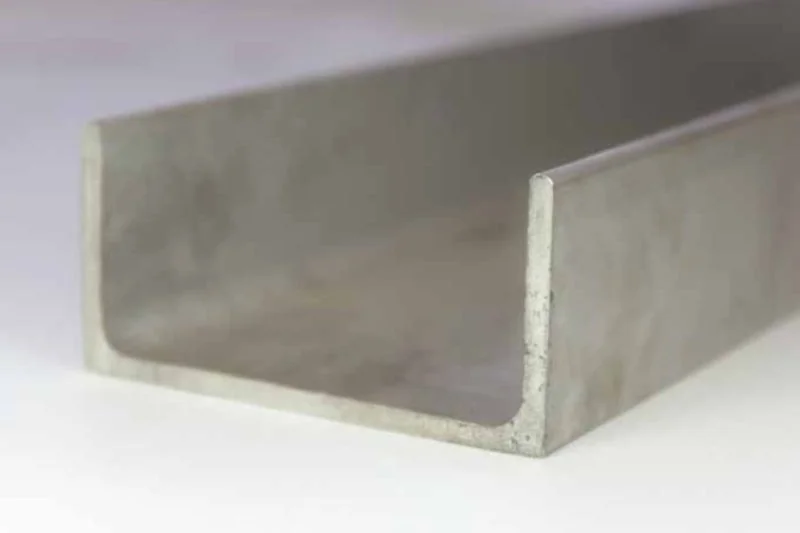

Austenitic steel is a popular option because of its formability, fabricability and ductility. It has excellent corrosion resistance and cleanability, with good hygiene characteristics. Grade 304 and Grade 316 are both austenitic stainless steel.

Grade 304 is a widely used austenitic stainless steel variety, thanks to its resistance to corrosion and excellent workability, weldability and impact strength.

Edcon Steel can source 304 stainless steel upon request.

Grade 304 is ideal for applications such as water piping, storage tanks, indoor electrical enclosures, wheel covers, automotive trim, kitchen equipment, appliances and decorative trim.

Grade 316 is a superior grade and is in stock at Edcon Steel. Known as the marine alloy, 316 has better resistance to corrosion and other stains than other types of austenitic steels (particularly in marine environments) and can retain its toughness over the broadest temperature range.

Grade 316 is ideal for applications such as chemical piping, pharmaceutical equipment, medical equipment, chemical equipment, stainless steel floats, structural steel and components in marine environments, and commercial kitchen surfaces, equipment and appliances.

Learn more about the differences between grade 304 and grade 316 here.

Cleaning stainless steel

Cleaning stainless steel will largely depend on the stain type, but the first step should generally be to clean stainless steel with warm water and mild soap or detergent. Simply use a soft cloth or sponge to gently scrub the surface to remove any dirt or debris.

For more stubborn stains, or for badly stained stainless steel, you should use a cleaning product containing phosphoric acid.

If your stainless steel starts to show signs of rusting or corrosion, then you should act quickly by applying an appropriate rust remover product followed by a protective coating like polyurethane varnish, in order to prevent further damage from occurring over time.

Protecting stainless steel

To protect your stainless steel, be sure not to use any abrasive cleaners or scouring pads, as these can damage the finish of the metal over time. And make sure to rinse off any soap residue with clean water before drying off the surface with a soft cloth.

For the best resistance to staining and discolouration, you should consider chemical cleaning (called passivation) as high or near to mirror polish as you can afford, along with a final electropolish.

A final word on staining with stainless steel is this – although unsightly for the customer in some situations, staining is a natural part of the protection of stainless steel. Unlike mild steel, the oxides (rust) on the surface of stainless steel protect the material below and stop corrosion from travelling further and causing more damage.

Things to avoid

In addition to regular cleaning, there are a few key things to avoid to adequately maintain your stainless steel. The first is to avoid using harsh chemicals like bleach or ammonia when cleaning your stainless steel, as these can cause discolouration and pits over time.

Some other key things to avoid:

- Wire brushes or steel wool made of carbon steel or stainless steel brushes previously used on carbon steel

- Shot blasting stainless steel surfaces with carbon steel shot, or any other shot/grit previously used for carbon steel

- Cleaning up brickwork around stainless steel with hydrochloric acid (muriatic acid, brick cleaning solution) – never splash this acid on stainless steel.

Buy stainless steel online from Edcon Steel

As Australia’s most comprehensive online steel and metal superstore, we have developed our huge range of steel products with you, our customer, in mind.

You can visit our stores to browse the range or pick up an online order. Our staff are on hand to answer any questions you have about our full range of products and services, so feel free to contact us for your steel or metal solution today.

Read More Steel Articles