Hit-and-miss engine: built using Edcon Steel products

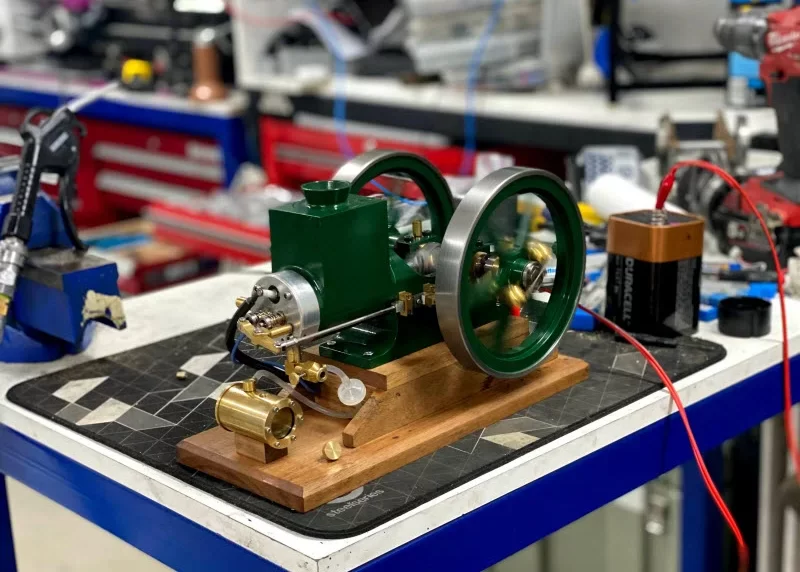

Congratulations to Jake Wright, a Melbourne based hobby machinist, on his amazing model hit-and-miss engine. Inspired by his great uncle, an engine enthusiast, Jake’s engine was based on plans by Jerry Howell (Farm Boy, no.853).

The inspiration

Like so many Australians, Jake’s life was upended by the COVID-19 pandemic.

“When the lockdowns started in early 2020, I was stood down from my job as a pilot and I needed something to keep myself busy,” Jake says.

While he had very limited experience in machining, he thought it might be fun to give something new a go.

“I had played around on a mini lathe before, but otherwise had no experience with machining. Armed with a Hare & Forbes catalogue and plenty of YouTube videos, I went out and purchased a small lathe and mill,” he notes.

Jake started with a small wobbler engine – a simple steam-engine design that doesn’t require a valve gear – before working his way up to a stationary steam engine.

“My great uncle, Don, had an incredible collection of 60+ old stationary engines dating back to the early 1900s that he had lovingly restored and kept in working order,” Jake reminisces.

“On the handful of occasions I managed to make the long trip over to see him, he would always tell me about the scale casting kits that were available on the internet, but I had never had the skills or machinery to even consider shipping cast iron from the other side of the world.

With that in mind and now a little bit of confidence under my belt with a couple of successful builds, I came across the ‘Farm Boy’ Engine, designed by Jerry Howell.”

The project

The design stood out to Jake as it was an internal combustion engine with the great sound of a hit-and-miss, but more importantly because it was a bar stock engine.

After finding Edcon Steel, Jake now had the ability to purchase any length of a large range of materials.

“I knew that I could save a bit of money over castings and if I made any inevitable mistakes, I’d just need to cut off another piece and try again,” he says.

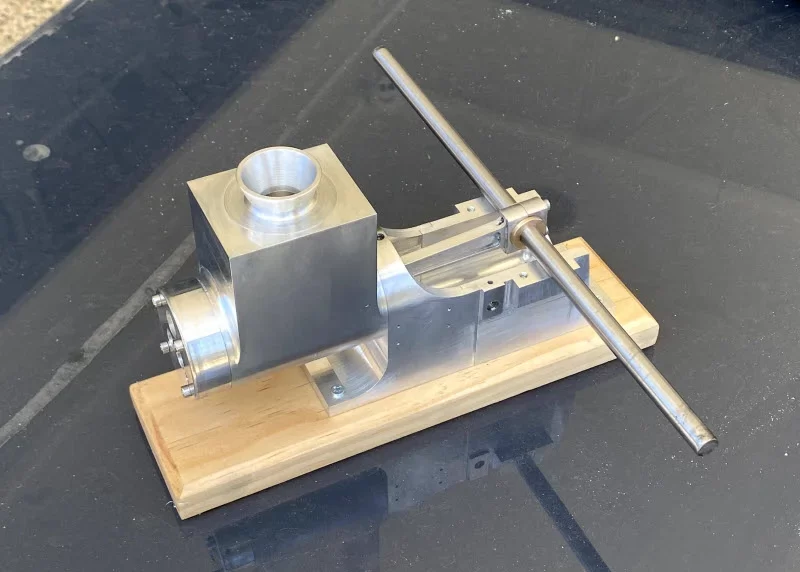

Jake set to work in early December 2020, and by Christmas, he had machined the mainframe, water hopper, cylinder cap and conrod from solid aluminium.

“My goal was to have something together that at least resembled an engine to be able to show Uncle Don at Christmas,” Jake explains.

“When I pulled it out of the box his face lit up with excitement (although it was nothing more than a stationary block of metal). He eyed it over in amazement at its similarity to the ‘real deal’ engines in the back shed.”

The final product

Amazingly, Jake’s engine came to life on the first attempt in March 2021, although still requiring plenty of tuning to get it to run smoothly.

He sourced the products easily from Edcon Steel, with every part of his engine machined from solid bar stock purchased from its stores, including:

- 76mm square aluminium for the frame and water hopper

- 155mm round cast iron for the flywheels

- Cast iron for the piston and cylinder liner

- Bronze for the bushings and valves

- Brass for the governor and features and fuel tank

- Steel crank

- Stainless steel pins and hardware.

“I can’t thank the guys enough for putting up with all these small ‘hobby’ orders and then posting them all way to Victoria for me,” Jake says.

“Can’t imagine how frustrating it must be to pull a length of 155mm cast off the rack to cut a 25mm slice!”

However, Jake’s accomplishment was bittersweet. His Uncle Don, who had been the true inspiration behind his project, lost his battle with lung cancer before seeing the engine run.

“I can only thank him for his support and advice along my journey of learning to machine and turn metal,” Jake says.

“I felt completely humbled by the kind words he said of my work, but more importantly, being able to see the happiness it brought him during this tough time.

This hobby has helped to keep me sane over these last couple of crazy years and I hope to continue the hobby to further my skills with future projects as the world now starts to return to some kind of normal and work finally returns.”

Are you looking for complete steel solutions?

Edcon Steel is Australia’s most comprehensive online steel and metal superstore.

We cut and supply steel and metal – in a wide range of shapes, sizes and grades – for all your project needs.

We know metal and steel – and we know our customers appreciate our service and stockholding, so feel free to contact us for your steel or metal solution today.

Like and follow us on Facebook to find out more about our next competition to be run later in the year.