Benefits of grade 250 mild steel sheet and plate

Mild steel

Here in Australia, many in the steel industry use the term ‘mild steel’. If they are talking about sheet and plate, chances are they are referring to grade 250 mild steel sheet and plate. While there are other grades of sheet and plate (200, 350 and 450 grade), most steel and plate used in structural, tank or general fabrication work uses grade 250 steel.

But, what does the number mean? Grade 250 mild steel is a reference to its strength. A grade 250 steel has a minimum yield strength of 250 MPa (Mega Pascals). This is typically 25 percent stronger in the same application than a 200 MPa strength steel.

So, the grade is somewhat of a strength rating of the steel, which engineers use to ensure the right steel is used for the job. For example, you can generally move or change from a lower strength steel to a higher strength steel, but you cannot normally go down in strength.

Mild steel is a carbon steel, rather than an alloy steel, as it does not contain large amounts of elements – like chromium or molybdenum. Known as ‘low carbon steel’, it typically has from 0.05% to 0.25% carbon content by weight. (It would be classified as cast iron if any more carbon were added.)

With low levels of both carbon and other alloying elements, mild steel has a number of distinct characteristics that make it a beneficial choice of material for a range of applications.

Here, we look into the benefits of grade 250 mild steel sheet and plates.

Grade 250 mild steel

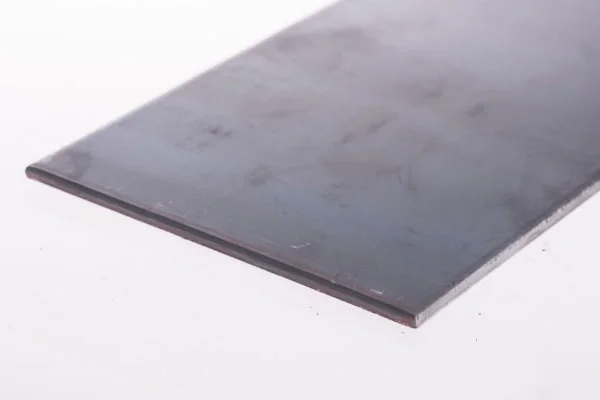

Grade 250 is one of the most common grades of mild steel in the Australian market and is used in the construction of bridges, steel tanks, high-rise buildings and general fabrication.

There are two separate types of grade 250 mild steel:

- Plate: made to Australian standard AS/NZS 3678, which is produced in flat plate form on a plate mill

- Sheet: made to Australian standard AS/NZS 1594, which is produced in coil form on a hot strip mill.

These two types of grade 250 mild steel have different characteristics, such as flatness, thickness and grain structure, so it’s important to find the most suitable product for your application.

Ductile and machinable

As mild steel has a lower carbon content, it is typically softer and more malleable than other steel types. Importantly, mild steel maintains this ductility in colder temperatures more than higher strength carbon steels.

Temperature has a dramatic effect on the ductility of metals, with low temperatures decreasing ductility and increasing the chance of cracking or fracture.

Mild steel does not begin to lose ductility until the temperature reaches freezing, whereas higher strength carbon steels can begin to lose ductility when they drop below normal room temperature.

The composition of mild steel also makes it machinable, which is why it is often used for welded fabrications and precision components.

The high amount of iron and ferrite in mild steel also makes it magnetic. While the limited amounts of alloying elements make it more susceptible to oxidation (rust), this can be mitigated by proper coatings.

Mild steel also has a high impact and tensile strength, good breakage resistance and excellent weldability and machinability.

Welding

Grade 250 mild steel, being the most common grade, is the simplest to weld using Australian welding standards AS/NZS 1554.1. The standards, and the welding industry, are well set up to support any user to weld grade 250 mild steel, with all welding suppliers stocking electrodes and wires suitable for these steels.

These consumables will also be the most cost-effective electrodes and wires available.

Further information about welding steel.

Lower cost

The composition of mild steel, with its low amounts of alloying elements and its cheaper processing costs, keeps the price of mild steel relatively affordable when compared with other steels.

It is this affordability, weldability and machinability that make it such a popular choice of steel for consumers, and the most widely used and produced steel here and around the world.

Edcon’s range of 250 grade mild steel sheet and plate

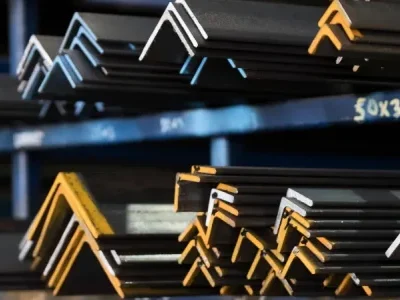

Edcon Steel is a metal expert… and mild steel is one of our specialities. Our mild steel options include angles, bars, boxes, beams, columns, pipes and plates. And we cut to size so you only pay for what you need (charges apply) and, subject to our freight option in your area, we can deliver.