Galvabond® vs Zincanneal®: What’s the difference?

When selecting products for your latest building job, construction project or DIY task, it is important to know which will be the most suitable for the applications. Certain types of steel and metal offer specific qualities that make them more suitable for the task at hand.

Galvabond® and Zincanneal® are two common types of metal that are both part of Bluescope’s Flat Products range. Both undergo the hot-dipped galvanising process, which involves applying a thin coating of zinc to the base metal, to shield it from environmental factors. Zincanneal®, however, undergoes a post-galvanising heat treatment process which converts the coating into a zinc/iron alloy.

Benefits of Galvabond

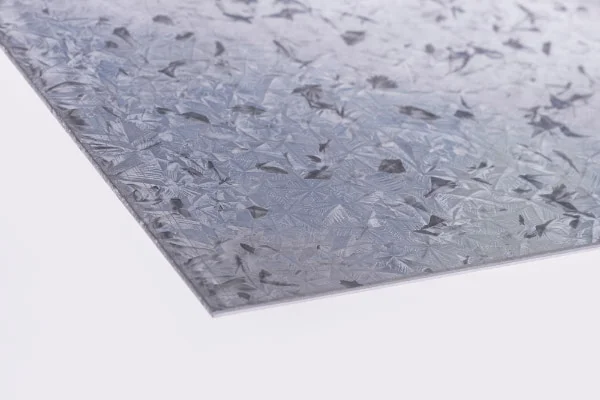

Galvabond® is simply galvanised sheet metal and has an easily recognisable and aesthetically pleasing spangled surface. It is widely available and suitable for general manufacturing and moderate drawing applications.

Not only does the surface of Galvabond® increase its corrosion resistance, the coating also has excellent adherence. The strong adherence properties means the sheet can be formed and folded without the coating peeling or flaking off making it a very versatile sheet.

The G2 Grade steel base is also designed with this in mind so Galvabond® steels can take a lot of ‘beatings’ before suffering any serious damage.

Galvabond® is suitable to form and bend and is perfect as a finish surface on external panels. It has good weldability so is easy to weld or solder. Used in a variety of applications, it can be profile or laser cut, formed and bent, drilled and welded for use in motor housings, meter boxes, automotive, domestic appliance, tanks and ducting and fume extraction.

Galvabond® enjoys all the benefits of galvanised steel, including longevity, lower costs, reduced maintenance, tough coating and reliability. While Galvabond offers significant benefits, it is not without its flaws. Galvabond® is difficult to paint without using acid-based etch primers, or waiting for the finish to dull and weather.

Benefits of Zincanneal

Zincanneal® is characterised by a matte grey, spangle-free, cohesive surface that is perfect for painting. This surface is achieved during the annealing process, where diffusion alloying is induced between the molten zinc coating and the steel.

Zincanneal® is also more suitable for welding and roll forming, making it a popular choice for both interior and exterior construction and maintenance projects and architectural applications.

It can also be profile or laser cut, formed and bent, drilled and welded for use in signs, doors, door frames, automotive panels, equipment and truck building and general fabrication.

While the smooth, even surface may be perfect for painting, it is important to note that, unlike Galvabond®, Zincanneal® must be painted for all external applications.

Edcon Steel’s range of products

As Australia’s most comprehensive online steel and metal superstore, Edcon Steel has a range of Galvabond® and Zincanneal® products to suit your application, all with a regular coating thickness of Z275, or 275g of zinc coating per square metre.

All our Edcon Steel stores have guillotines available to cut both Galvabond® and Zincanneal® sheet to your custom size – you only pay for what you need. As such, we have plenty of smaller offcuts available at a discounted rate to assist those customers with smaller requirements.

Read more steel articles to find out more about the steel industry, customer projects and product resources.