Custom drill bit: a genius hack for an ongoing problem

At Edcon Steel, we love seeing the ways our customers solve tricky problems.

Adam, a runner-up in our stainless steel project competition, solved a particularly challenging problem with a simple, yet effective solution!

Using his ingenuity and skill (and Edcon Steel 316 stainless steel products), Adam created a custom drill-bit prototype that proved a genius hack for production line workers at a large food manufacturing plant.

The inspiration

A qualified mechanical fitter and turner, Adam works as a contractor for a number of large manufacturing companies.

One of his clients – a food and beverage manufacturer – was having a problem on their production line, and they needed Adam to solve the issue.

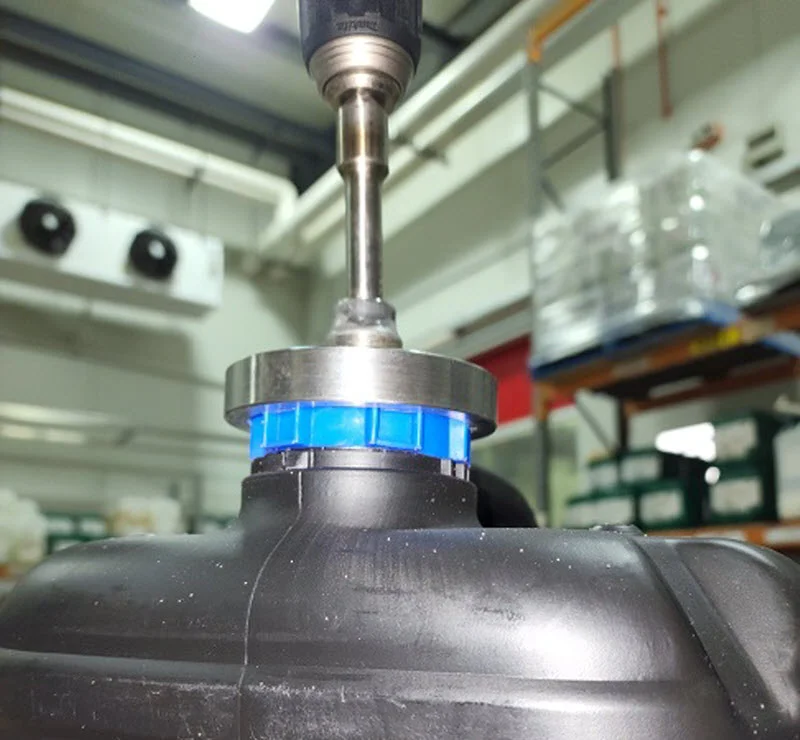

Production line workers were using hand-held keys (and sometimes their palms) to open 20L drums.

If you’ve ever opened a full 20L drum you know that this isn’t sustainable, day-in, day-out.

The management team was worried that the repetitive hand movements of this technique, which puts pressure on nerves that run through the wrist, could cause serious issues for their workers, like carpal tunnel syndrome.

They requested that Adam develop and manufacture a prototype drill bit or chuck that would take the pressure (quite literally) off their workers.

The project

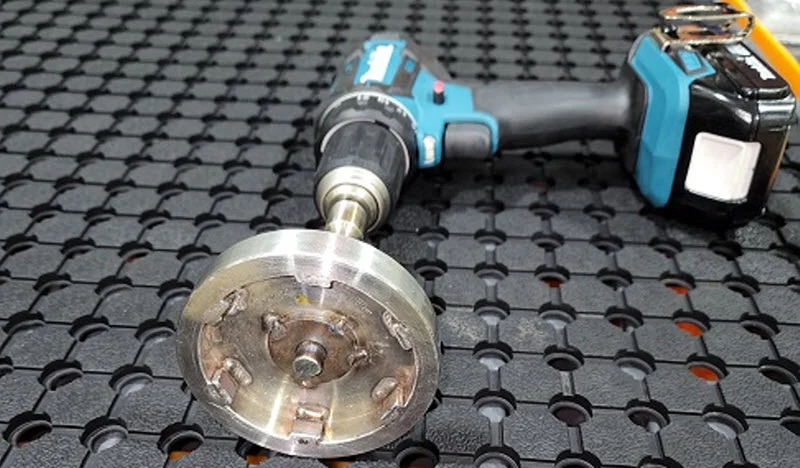

Adam saw a simple and effective solution: a drill with a custom-built piece that would fit the lids and open the drums easily.

“It was really quite simple,” Adam says.

“I machined the round bar to mimic the plastic handle of the drums, then I worked on the flat bar, making lugs to fit inside the 20L cap, with its grooved ridges.

After boring a hole to take a 19mm stainless steel socket, I TIG welded it into the base as the connection point.

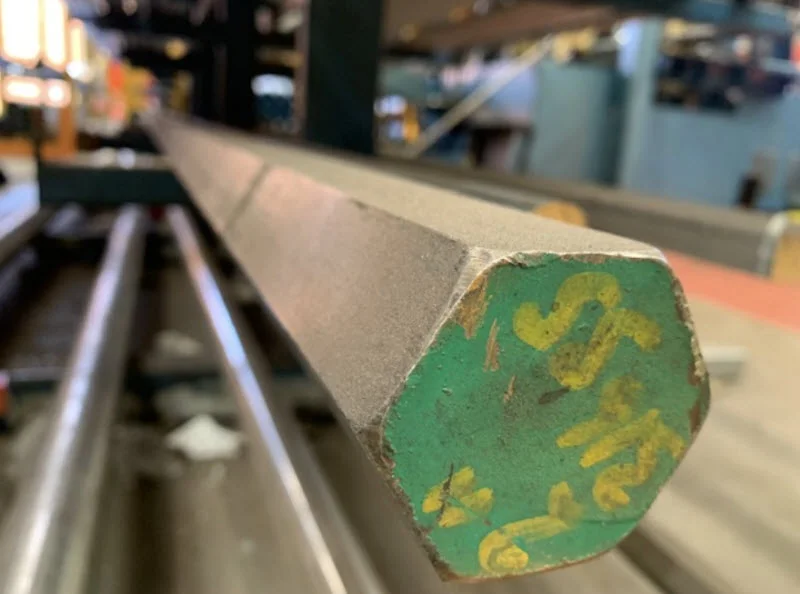

I purchased hex bar from Edcon for the drill chuck adapter and welded it to the stainless steel 3/8 extension to be held by the drill chuck.”

Upon testing the unit, workers observed that some of the lids were getting stuck in the drill chuck, so Adam was tasked with constructing an ejector pin that would remove the lids after each use.

“I had some stainless steel round stock laying around, so I made an ejector pin that would remove the lids,” Adam explains.

“Using a spring and cover plate, I weld-fitted and tack-welded it all together to see how it went.

This works well as the spring compresses when the chuck is pushed down on the lids, then pushes the cap out when it is lifted off. So far it is working great. The production line workers are able to open lids with minimal force and it also removes the need to remove the sealing ring prior.

Seeing as this is for a large Australian food manufacturer, I’ve been told there is potential for this system to be rolled out Australia-wide.”

Sourcing materials

When sourcing materials, Adam was limited due to the nature of the production facility.

Being a food manufacturer, hygiene was crucial and appropriate sanitisation was necessary for all equipment.

Adam selected 316 stainless steel as it can withstand corrosion from the oxidising acids contained in cleaning products.

“I purchased the round bar stock and flat bar for the tabs from Edcon Steel in Blacktown,” Adam says.

With his workshop situated across the road from the Blacktown store, Edcon has always been Adam’s supplier of choice.

“The biggest selling point for me is that Edcon cuts to size,” Adam says.

Are you looking for complete steel solutions?

Edcon Steel is Australia’s most comprehensive online steel and metal superstore. We cut and supply steel and metal – in a wide range of shapes, sizes and grades – for all your project needs.

We know metal and steel – and we know our customers appreciate our service and stockholding, so feel free to contact us for your steel or metal solution today.