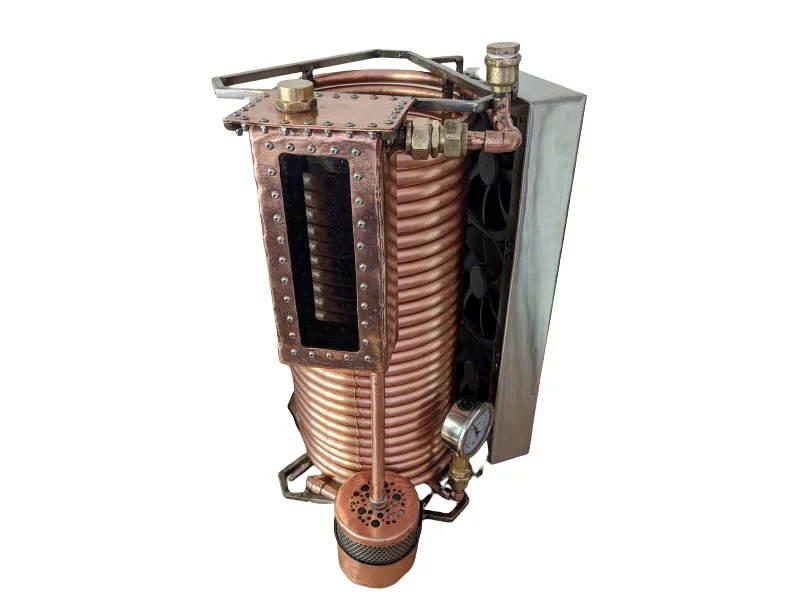

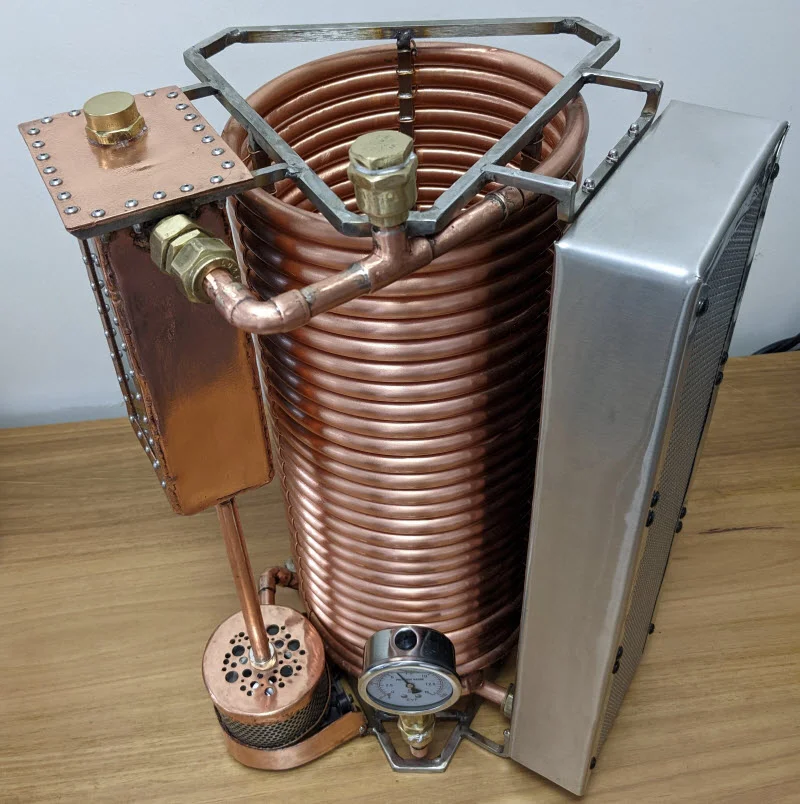

Custom external computer water-cooling system

Just when we think our customers couldn’t surprise us anymore…

Edcon Steel customer Matthew Pearson blew our minds with his custom external computer water-cooling system.

Intricate, functional and aesthetically pleasing, this project takes ‘thinking outside the box’ to a new level.

The inspiration

When Matthew decided it was time for a new computer, he was conscious of the heat generation a high-end PC can produce. As a civil engineer, he decided to put his skills to use and build a custom external computer water-cooling system.

“With summer coming (and the need for a new high-end PC filled with hot running components) around the corner, I wanted a solution that could silently cool the PC and not heat up my room,” explains Matthew.

“An external water-cooled system provided a solution as it transports heat away from the computer through flexible hoses to an external device to radiate heat elsewhere.

I also wanted to challenge myself and build something a bit unique, fabricating my own water-cooling components.”

The project

Using no plans or guides, Matthew designed the entire system himself.

The water-cooling system comprises three fundamental components: a pump, radiators and a reservoir. But considering the intricacies of the project, we thought Matthew best to explain how it functions.

“It works by pushing water through a heat source (PC) and then through the radiators to cool the water,” he explains.

“A reservoir assists with filling the system and provides an air pocket for expansion or contraction and to cover any fluid loss that might occur when connecting and disconnecting the PC. The pressure gauge was provided to indicate pump operation.

And then there’s the copper coil, which works as a passive radiator. The stainless-steel-clad rectangular structure houses a radiator and three fans to form an ‘active’ radiator.

When the water temperature increases to a prescribed temperature, the fans will turn on to provide further cooling.

The reservoir is constructed from a welded copper sheet with acrylic sheets to form windows.

Then I constructed the pump housing from copper and perforated stainless steel sheet.

When switched on, the pump has internal LED lights that light up and shine through the holes in the housing.”

With very minimal metalwork and fabrication experience, it was a steep learning curve for Matthew.

“The total of my metal working experience is quite minimal,” he explains. “This was the first time I have welded stainless steel and copper, so it there was a lot of experimentation. There was a lot of fixing things up. I blew holes in metal so many times. “

“One thing I’ve learned from this project is just how different metals can behave. Copper is soft and easy to drill and cut, whereas stainless steel can be challenging to cut or drill. Copper also conducts heat many times faster, making welding more challenging, and I found that I had to use much higher amps for comparable thicknesses.”

Sourcing materials

From the outset, Matthew knew that stainless steel, copper and brass were the materials he needed for the project.

“Typically, when you have a water cooler computer you have a stainless steel pump and the water blocks for heating are often copper,” he says.

“If you input other metals, then you get galvanic corrosion and all sorts of other problems.”

With this in mind, Matthew headed to Edcon Steel at the suggestion of his father.

He constructed the system using 1.2mm copper sheet and a 316 stainless steel sheet (0.7mm brushed and perforated).

“Edcon Steel cut the stainless steel sheet, which was great. There’s no way I would have been able to cut that so nice and straight with my tools.”

Matthew constructed the frame by welding stainless 316 steel (8x8mm and 6x6mm square bars). All piping is 12.7 OD copper tube.

As for the remainder of the project, that’s on pause for the time being as many of the computer parts haven’t been released yet.

But we’re excited to see how it turns out!

Are you starting a DIY project?

At Edcon Steel, we pride ourselves on our level of customer service and the depth of our industry knowledge. Our experienced staff will provide insight and support on all of our steel, metal and industrial products.

Whether you are in-store to browse the range or are making an online order, our staff are on hand to answer any questions you have about our full range of products and services, so feel free to contact us for your steel or metal solution today.