Edcon Tool Box

Why you should use gal fencing this season

Read more

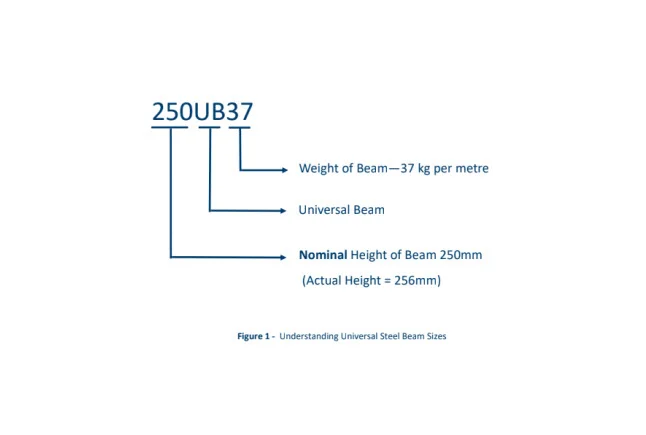

Beginners Guide to Structural Steel Beams

Read more

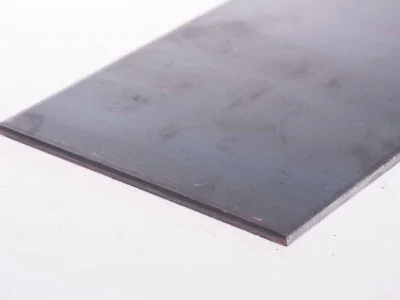

Benefits of grade 250 mild steel sheet and plate

Read more

Stainless steel: six common questions

Read more

Reasons to use structural steel

Read more

Tool steel grades explained

Read more

Galvanised steel tube coatings

Read more

Heat treating processes for metals

Read more

The importance of steel protection

Read more