Finn’s Satellite Ground Station: Building an antenna rotator using aluminium round tube

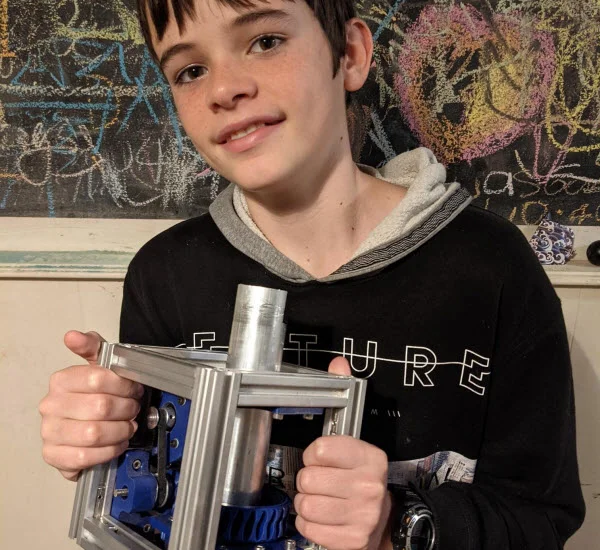

One of Edcon Steel’s youngest customers, 13-year-old Finn, recently entered our inaugural project competition with his ground station project and antenna rotator using aluminium round tube.

The team at Edcon Steel was so impressed with Finn’s entry that we wanted to share his project with our audience.

Tracking satellites

Finn’s fascination with satellites began when he and his father, Stuart, built a satellite tracker some years ago.

Tapping into publicly available information on the US Air Force Space Command website, they were able to retrieve data on all satellites orbiting the earth.

Finn and Stuart wrote a computer program that allowed a motorised base to point a pen at the nearest satellite above them at any given moment.

During the course of the project, Finn noticed that the motorised pen was locking onto satellites that were not listed on other satellite tracking websites.

“Finn started wondering what satellites these were, and we were interested in whether there were ‘spy satellites’. ”

“It was probably a bug in our code, but it really sparked his imagination,” Stuart said.

The project

Finn, a member of his school’s STEM class, needed a bigger project and had heard about the SatNOGS (Satellite Networked Open Ground Station) project.

SatNOGS is a free software and open-source hardware platform which aims at creating a network of satellite ground stations, with over 300 across the world. For those unfamiliar, a ground station is like a radio that is designed for telecommunication with spacecraft, or to receive radio waves from astronomical radio sources like satellites.

“You can find out all sorts of information, like the temperature of spacecraft and how much power their solar panels are making,” Finn says. “And you can download weather satellite images, too.”

But as satellites are not stationary, ground stations must have motorised antennae that can rotate to follow satellites as they move across the sky.

So… Finn set to work to construct the antenna rotator.

A work in progress

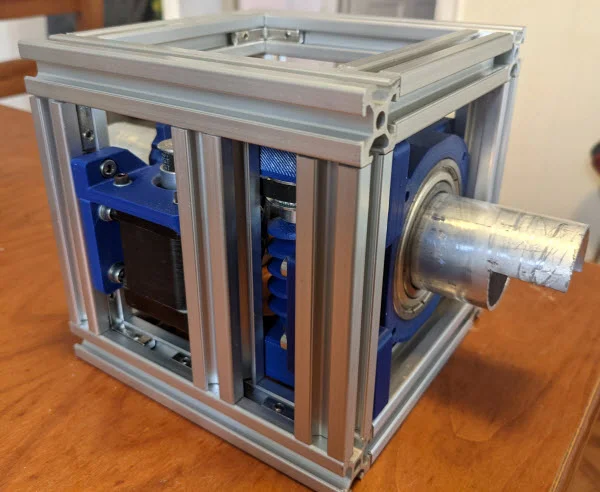

Finn’s antenna rotator moves an antenna with a Raspberry Pi to point at satellites.

But it’s a work in progress, thanks to its complicated design and hard-to-source materials… and his school homework getting in the way.

“I’ve had to juggle my school work and assessments, so it’s taken longer than expected,” says Finn.

“We also had to get a 3D printer to be able to print some of the parts.”

Finding the right kind of aluminium tube for the shaft of the antenna rotator also turned out to be harder than anticipated.

“That’s how we came across Edcon Steel,” Stuart says. “We were having trouble finding the right kind of tube, but then we found Edcon and they sold exactly what we needed.”

Finn is already getting started on other projects too, with a basketball pole in the making. He’s even learning how to weld for the project.

“Dad and I have been welding the frame together and if I do that more and gain more confidence, then I can move onto more welding projects,” Finn says.

Are you looking for complete steel solutions?

Edcon Steel is Australia’s most comprehensive online steel and metal superstore, so if you’re looking for products for your next project, we’ve got you covered. We cut and supply steel and metal – in a wide range of shapes, sizes and grades – for all your project needs.

Read more steel articles to find out more about the steel industry, customer projects and product resources.