All about engineering steel

Many people regard engineering steels as the workhorses of steels because they are widely available, economical in cost and easy to process. They are also typically more responsive to heat and mechanical treatments than other steels.

Here, we cover the basics of engineering steel so you can make more informed building and buying decisions.

What makes engineering steel different from other types of steel?

The biggest difference between engineering steel and other types of steel comes down to the alloying elements. Engineering steel has small amounts of one or more alloying elements, other than carbon, added to produce specific properties that are lacking in regular carbon steel.

These alloying elements, like manganese, nickel or titanium, affect properties such as formability, strength, corrosion resistance and welding performance.

For example, the strength achieved with engineering steel depends on the alloying elements, as well as the heat-treated state of the material.

Annealed or normalised engineering steels will have lower strengths than heated and rapidly quenched steels. This means it is best to look at a material data sheet to determine what strengths a particular product can achieve.

Engineering steel grades

Steel grades act as common guidelines that set out the composition, mechanical properties, tolerances on dimensions, manufacturing method and quality control provisions that are specific to each material.

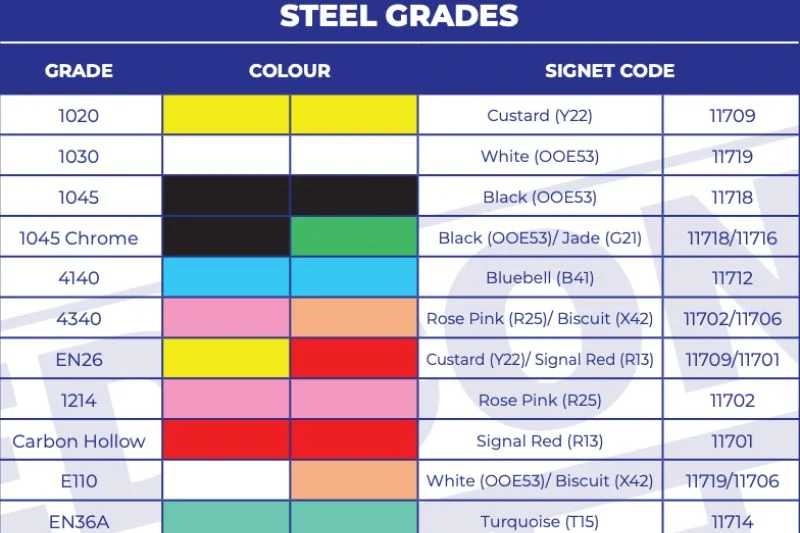

Choosing the wrong steel grade can be disastrous, so it’s important that you understand which grade is right for your application. Standardised colour coding enables you to distinguish different types of steel based on their unique metallurgical properties.

Generally categorised into carbon steels and alloy steels, Edcon Steel’s range of steel products has varying combinations of carbon, iron and other elements.

View our steel grade colour guide here.

For more information on engineering steel grades, check out this helpful article.

Edcon’s range of engineering steel

Edcon Steel is a firmly established, quality supplier of engineering steel for a range of sectors, including hobby, industrial, infrastructure and defence.

Edcon Steel stocks a wide range of engineering steel, available in various shapes and sizes, so click on the product groups below to find the right steel for your next project.

Bright Mild (BMS) in round bar, flat bar, square bar

1045 medium tensile round bar

1045 and 4140 chrome bar

High-tensile hollow bar

4140 (centreless round bar and round bar)

4340 (round bar)

EN26 (round bar)

Case Hardening

High-Speed Steel (HSS)

Key Steel: 304 stainless and zinc-coated in flat and square bar

Buy steel online from Edcon Steel

At Edcon Steel, we pride ourselves on the expertise of our staff, our level of customer service and the depth of our local market knowledge.

You can visit our stores to browse the range or pick up an online order.

Our staff are on hand to answer any questions you have about our full range of products and services, so feel free to contact us for your steel or metal solution today.