304 vs 316 stainless steel: Understanding stainless steel grades

Some of the most common questions people ask at our steel stores are about stainless steel: Which stainless steel should I use for my project? Which grade is better?

Here, we answer some of your questions by revisiting one of our most popular articles about two common stainless steel grades: 304 vs 316 stainless steel.

Stainless steel 101

While all steels have the same foundational iron and carbon composition, stainless steel is the general term for a group of corrosion-resistant alloy steels that contain ≥ 10.5% chromium.

Chromium is the alloying element that allows stainless steel to withstand prolonged atmospheric exposure and use before showing signs of wear or corrosion.

While both carbon steel and stainless steel contain iron – which oxidises when exposed to the environment – the added chromium in stainless steel makes it more corrosion resistant.

Many grades fall under the stainless steel umbrella, each with slightly different chemical compositions and physical characteristics: this is important when selecting the correct grade for your own application.

For projects that require high corrosion resistance, austenitic stainless steels are optimal as they contain high amounts of nickel and chromium, alloys that offer exceptional corrosion resistance. Both 304 and 316 stainless steel are austenitic grades, which means they have excellent mechanical properties.

The differences

Understanding the differences between 304 and 316 stainless steel is important when selecting materials for your application.

Chemical composition

The main difference between 304 and 316 stainless steel is the presence of molybdenum, an alloy that enhances hardenability, strength, toughness and resistance to wear and corrosion. While both grades are considered austenitic grades, only grade 316 contains molybdenum.

Commonly known as ‘kitchen grade’, 304 grade stainless steel contains from 16 – 24% chromium and up to 35% nickel, as well as small amounts of carbon and manganese. The remainder of the chemical composition is primarily iron.

Grade 316 stainless steel is commonly called ‘marine grade’ stainless steel, as the higher content of nickel and chromium, plus the inclusion of molybdenum, enhance its corrosion-resistant properties and suitability for marine environments. While iron remains the major component of grade 316 stainless steel, it also contains silicon, manganese and carbon.

Applications

The high amounts of chromium and nickel give 304 stainless steel good corrosion resistance, making it an excellent choice for kitchen appliances, food processing equipment, piping, finishing hardware and accessories, and indoor panels and sculptures.

However, grade 304 stainless steel will struggle in more corrosive environments like swimming pools, chemical processing equipment and medical equipment. Grade 316 stainless steel is often prefered in these applications, particularly when exposure to salt may be an issue.

Grade 316 stainless steel can also be found in products related to the food and beverage industries, particularly commercial kitchens and food processing plants, as it has a higher resistance to chlorides; is able to withstand shock and abrasive conditions; and does not react to acids found in milk, cooked foods, vegetables and food additives.

Strength and workability

Austenitic steels like 304 and 316 stainless steel ensure a versatile balance of strength, workability and corrosion resistance, making them ideal for outdoor architectural features, surgical instrumentation and food processing equipment.

However, while the molybdenum content in grade 316 increases corrosion resistance, it can affect formability and machinability.

Cost

Cost is another major difference between these stainless steel grades, as grade 316 is generally more expensive than grade 304.

If you have an application with very powerful corrosives or one that relies on chlorides, then paying a premium for grade 316 stainless steel will result in a product that will last many times longer than grade 304 stainless.

However, for applications using milder acids or where salt exposure isn’t a concern, grade 304 stainless steel can work just as well.

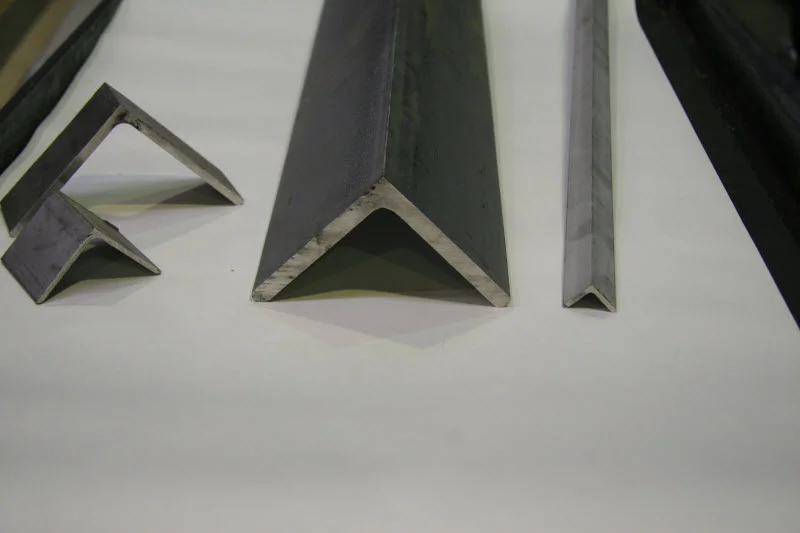

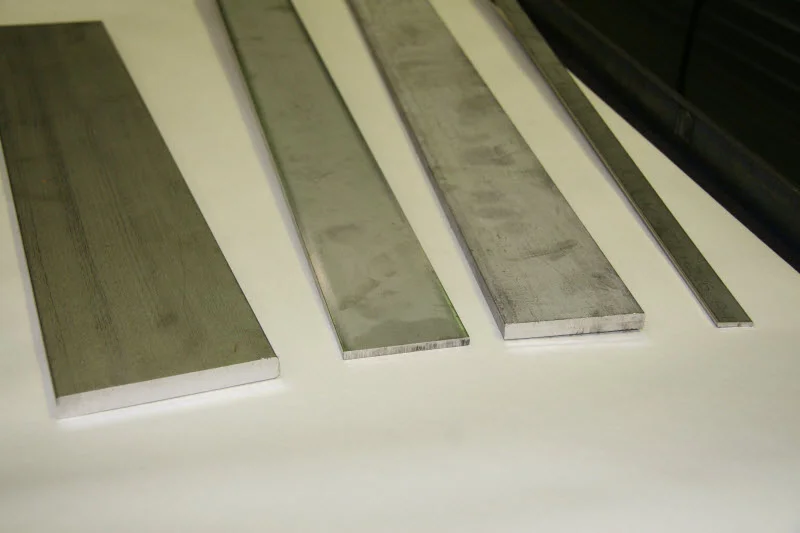

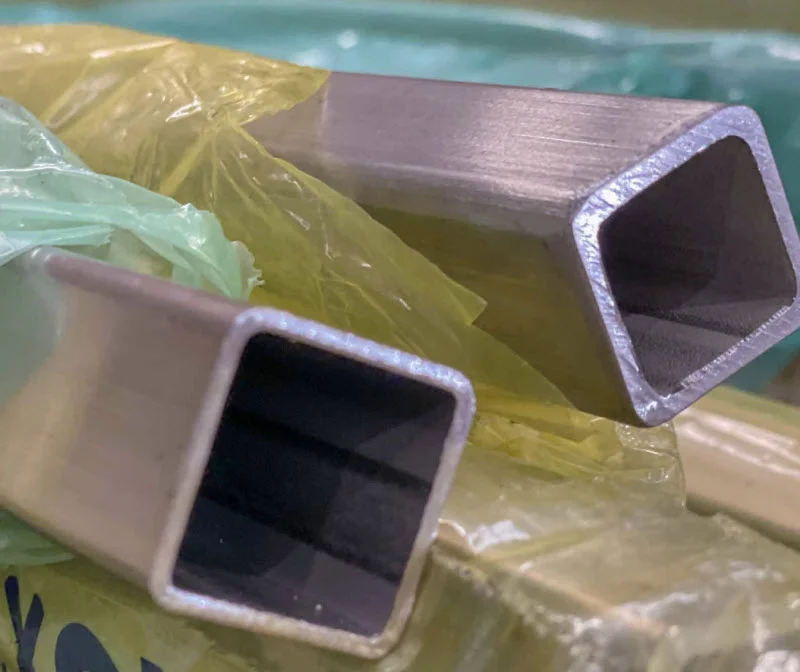

Edcon Steel stocks a wide range of grade 316 stainless steel, cut to size as required. If you require grade 304, just let one of our team know, and we can order as required. However, as grade 304 is on individual orders only, we only sell it in full sheets or lengths.

Are you looking for complete steel solutions?

Edcon Steel is Australia’s most comprehensive online steel and metal superstore. We cut and supply steel and metal – in a wide range of shapes, sizes and grades – for all your project needs.

We know metal and steel – and we know our customers appreciate our service and stockholding, so feel free to contact us for your steel or metal solution today.